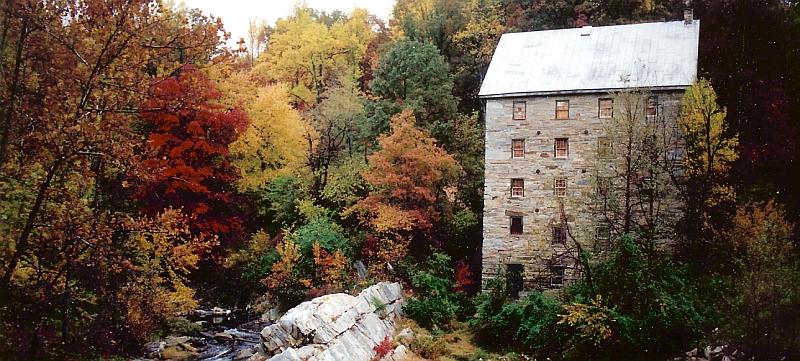

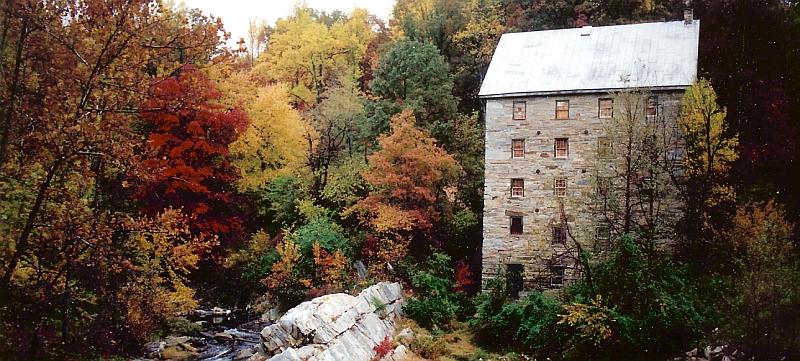

How Restoration Progressed: Phase IThe Chapman's Mill stabilization project is a unique and valuable undertaking in the field of historic preservation. TTMAC has chosen to preserve the Chapman's Mill as a ruin site, showcasing the architectural, engineering and historic elements of the building as it stands after the fire of 1998. Cutting-edge technology is being used for the structural stabilization of the mill building. An internal anchoring system, developed in Europe for historic masonry buildings, has successfully been implemented in Phase I of the project by Cintec America. Recently completed in May 2004, Phase I includes the structural stabilization of the south wall (actually seven stories high and in the worst condition) and corners, lead capping on all upward facing surfaces of the entire building and emergency shoring of all window openings (49 total).The engineering for the stabilization of the north, east, and west walls is ongoing and the work will be completed in the spring of 2006 as the weather dictates. Chapman's/Beverley Mill is believed to be the tallest stone building in the United States. The contractors chosen for this specilaized historic preservation project are experts in their fields. They are Cintec America, Inc. - Structural Anchoring Systems, Conservation Solutions, Inc. - Project Management, Standard Restoration and Waterproofing - Masonry and Scaffold Resource, Inc. - Scaffolding. Phase II stabilization of the last three walls, should be completed by July 2006. |

|

|

First posted May 7, 2006 Last update Jan 25, 2020 |